Welcome to the Kataria Tech Zone blog! In the world of craftsmanship, few advancements have had as profound an impact as the introduction of CNC (Computer Numerical Control) routers. These machines have moved woodworking from a purely manual, time-intensive craft to a highly automated, ultra-precise manufacturing process. If you’re in the woodworking industry—from custom furniture making to large-scale cabinet production—understanding the power of the CNC router is key to staying competitive.

The Precision and Consistency Advantage

The most significant shift brought by CNC routers is the unparalleled precision and consistency they offer.

- Flawless Accuracy: CNC machines follow digital instructions (G-code) generated from CAD/CAM software. This means they can execute intricate cuts, complex joinery, and detailed engravings with microscopic accuracy, eliminating the variability and human error inherent in manual methods.

- Perfect Repeatability: For mass production, custom cabinet lines, or multi-part projects, a CNC router can replicate the exact same part thousands of times. This ensures every piece fits together flawlessly, drastically reducing assembly time and material waste.

Versatility: Beyond the Straight Cut

A CNC router is not just a glorified saw; it’s an all-in-one manufacturing center that offers incredible versatility across countless applications:

- Furniture Manufacturing: Creating curved table legs, intricate chair backs, and customized panels.

- Cabinet Making: Efficiently producing consistent cabinet doors, shelving, and complex joinery using techniques like nest-based manufacturing (NBM) to maximize material yield.

- Architectural Millwork: Carving custom crown moldings, decorative wall panels, and detailed banisters.

- Signage and Art: Cutting 3D letters, logos, and complex relief carvings on wood and other soft materials.

- Prototyping: Rapidly producing scale models for architects and engineers.

The Business Benefits: Speed, Efficiency, and Cost Savings

For any business, the investment in a CNC router translates directly into tangible operational and financial advantages:

| Benefit | How the CNC Router Delivers |

| Increased Productivity | Automates repetitive tasks, allowing for continuous, high-speed operation, drastically cutting project lead times. |

| Material Optimization | Advanced nesting software intelligently arranges parts on a single sheet of material to minimize off-cuts and reduce waste, lowering material costs. |

| Reduced Labor Dependence | One trained operator can manage the production of components that previously required multiple skilled laborers and machines. |

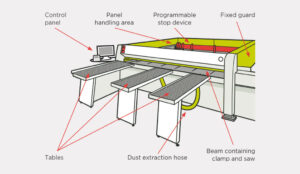

| Enhanced Safety | By automating the cutting process, the machine reduces the operator’s hands-on interaction with sharp tools, improving overall workplace safety. |

Conclusion

CNC routers have cemented their place as an essential tool, moving woodworking from traditional craft to a high-tech, scalable industry. They empower woodworkers to achieve levels of complexity, precision, and efficiency that were once impossible, allowing businesses to save money, scale production, and unleash new creative designs.